Reviews

User Score

Rate This

Descriptions:

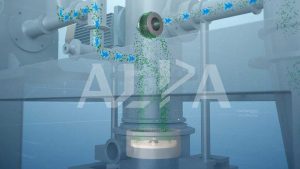

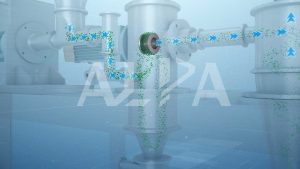

Powder surface modification has important practical significance for improving the performance of the powder, improving its practical value and opening up the development of application fields.

In plastics, rubber, adhesives and other polymer materials and composite materials, non-metallic powder fillers, such as calcium carbonate, kaolin, talc, quartz, wollastonite, asbestos, magnesium hydroxide, aluminum hydroxide, etc., must be The surface of the filler is modified to enhance its compatibility with the matrix, dispersibility, mechanical strength and comprehensive performance.

Surface modification is one of the necessary processing methods for fillers to change from target fillers to functional fillers. It is also the main purpose of mineral filler surface modification.

High activation degree modification of irregular shape, ultra-light, ultra-fine, viscous, agglomerated materials such as flake needles, under the condition of meeting the modification mechanism and process conditions (the key is the dispersibility of materials and additives), the use of high energy It is a good method to complete the modification during grinding.